A gate is a just a gate, right? Well, there are differences between a five-bar gate and an industrial security gate. And swing gates operate very differently from sliding gates. And sliding gates are like cantilever gates but only one needs a track.

So, with all these differences and variations in size, weight, materials, location and operation, how do you choose the right gate automation to turn manual gates into automated gates? Here’s our starter guide to the different types of gate automation available and what works best where.

Swing Gates

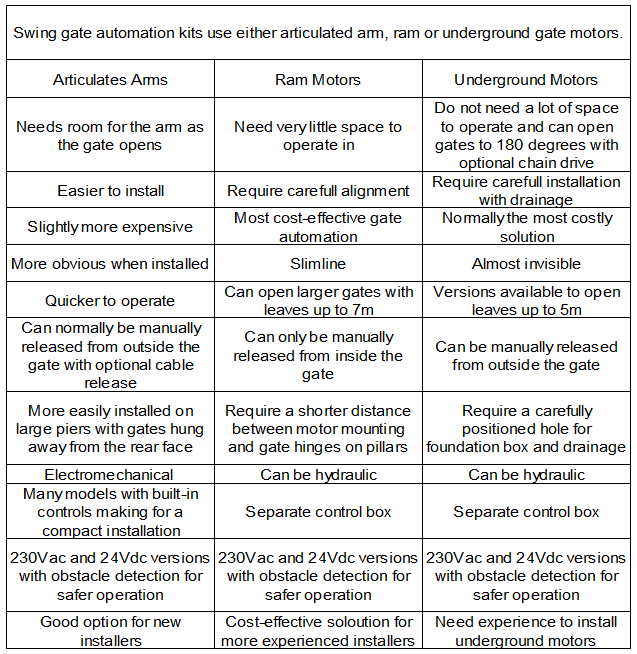

Swing gates have the largest range of automation systems. There are ram style motors, articulated arm motors and underground and in-post gate operators.

Rams

Rams are long and thin. They’re mounted at one end to the gate post and the other end is mounted on the gate. This end is extended out of the motor housing to open the gate and retracted back into the housing to close it. They use either hydraulic pistons or linear screws where a threaded shaft is turned to move the gate attachment point up and down the threaded shaft.

Articulated Arms

Articulated arm motors have a jointed metal arm attached to a motor output. The motor housing is mounted to the gate post and the end of the arm is attached to the gate. When the motor turns, the articulated arm opens or closes the gate.

Underground and In-post motors

Underground motors and in-post motors are discrete gate operators and are either sunk into pits beneath the gate hinge point or installed within the gate post. Arms connected to the hidden gate motors are then attached to the base of the gate.

Rams need a little care to get the geometry right but they’re strong. Articulated arms tend to be a little more tolerant of slight installation inaccuracies and, like rams, have the gate mounting away from the gate hinge so need less force to open and close gates. Undergrounds and in-post motors usually require careful installation and undergrounds need good drainage. They both operate gates from the hinge and need a lot of force as a result.

Sliding Gates

Sliding gate motors push a single rolling gate along a track mounted along the gate’s travel. A gear mounted on the motor output shaft and protruding from the motor housing meshes with a rack mounted along the length of the gate. Cantilever gates work in a similar way but don’t need track along their length as they’re counter-balanced around a single rolling support point.

Have a look at the illustrations included to see more details of the various types of gate motors. You can also use the table below to see all gate motors types compared against each other.

Garage Door Automation

Automatic garage doors are great. You arrive at your garage in your car, press a button and the garage door opens magically. Drive your car into your garage and the door closes at the touch of a button.

Photo Beams

A standard on most gate systems, one or two infrared beams are recommended to prevent gates closing on to vehicles or pedestrians. It is better to prevent an impact than act after the impact has happened.

Contact us

32/509 Nakkara Arcade

Near Civil Station

Irinjalakuda North

Thrissur,Kerala

Pin-680125

+91-4802820489

+91-8111931489

No comments:

Post a Comment